Thiết bị lắp ráp FS / PCB & Phụ tùng PHỤ KIỆN SMT Nhà cung cấp-Panasonic | Yamaha | FUJI | Samsung | Hitachi | JUKI

Máy cắt laser lưới thép PCB SMT Stencil để hàn dán in

|

|

What is an SMT Stencil Cutting Laser Machine?

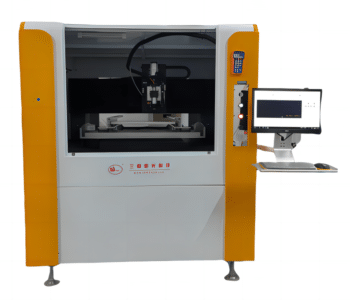

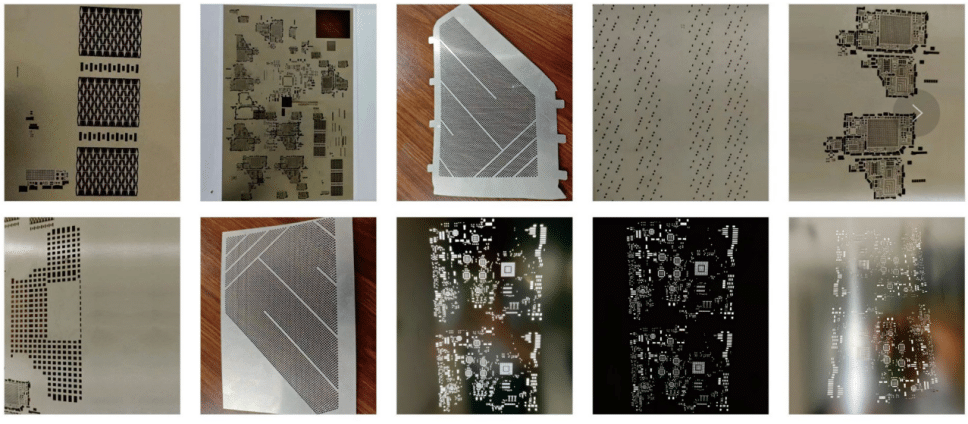

An SMT stencil cutting laser machine is a specialized equipment designed for the precise cutting of stencils used in SMT assembly processes. You can set and import your stencil drawings to achieve arbitrary cutting. These machines utilize advanced laser technology to accurately cut or drill in stencil materials, such as stainless steel or nickel, creating custom stencils tailored to specific PCB designs.

Key Features of Laser Cutting Machines for SMT Stencils

1. Precision Cutting: Laser machines offer exceptionally high precision, ensuring clean and accurate cuts even for intricate patterns and fine details.

2. Speed and Efficiency: Compared to traditional methods like chemical etching or manual cutting, laser cutting is incredibly fast, optimizing production efficiency.

3. Customization: Laser technology allows for easy customization of stencil designs, accommodating various PCB layouts and component configurations.

4. Automation: Many modern laser machines are fully automated, reducing human intervention and minimizing errors during the cutting process.

Applications of Laser Cutting in SMT Stencil Fabrication

. PCB Prototyping: Laser cutting is ideal for rapid prototyping, enabling quick turnaround times for stencil iterations during PCB development.

. High-Volume Production: In large-scale PCB manufacturing, laser cutting ensures consistent quality and uniformity across multiple stencils.

. Fine Pitch Components: Laser machines excel in cutting stencils for fine pitch components, where accuracy and alignment are critical.

Select the best SMT steel mesh cutting laser machine

When choosing SMT steel mesh cutting laser machine, please consider the following factors:

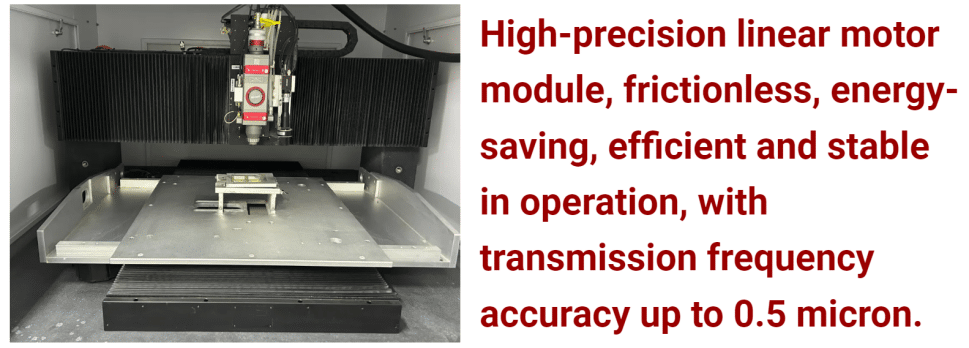

Cutting accuracy: looking for high-resolution optical devices and precision control systems of the machine to achieve the required cutting accuracy.

Material Compatibility: Make Sure the machine is compatible with all kinds of template materials, including metals such as stainless steel and polymer.

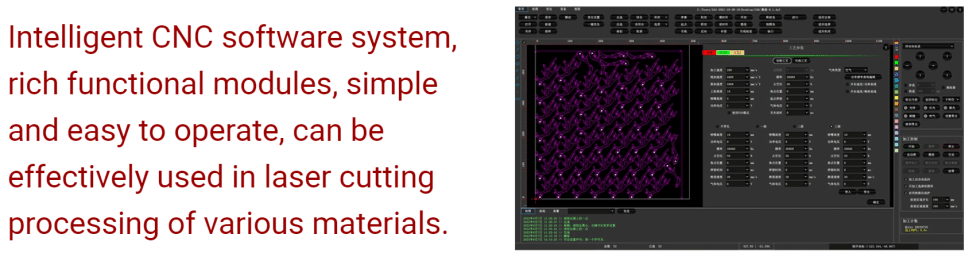

Software Integration: choose machines that seamlessly integrate with template design software to simplify workflow and design changes.

Support and maintenance: select reputable suppliers to provide comprehensive support and maintenance services to maximize the machine’s uptime and service life.