Thiết bị lắp ráp FS / PCB & Phụ tùng PHỤ KIỆN SMT Nhà cung cấp-Panasonic | Yamaha | FUJI | Samsung | Hitachi | JUKI

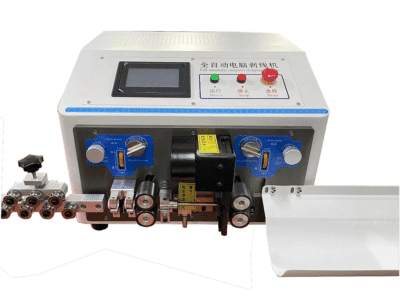

Máy tuốt vỏ cáp dây tự động Dụng cụ tuốt dây điện công nghiệp

|  |

Tính năng:

- Adopt the latest 32-bit intelligent control system, LCD with Chinese and English switching.

- Touch screen operation is simple and convenient

- Can store 100 messages and call and view them at any time

- High precision and efficiency, suitable for mass production.

Benefit:

- Increased Efficiency: Automatic wire strippers can handle high volumes of wires quickly, significantly reducing manual labor and time spent on each job. This is ideal for large-scale or industrial operations.

- Precision and Consistency: With computerized control, these machines offer precise stripping cables without damaging the wire core, ensuring uniform results across multiple wires.

- Versatility: These machines can strip a wide range of wire sizes and types, from fine electronic cables to larger industrial wires, making them adaptable to different tasks.

- Reduced Human Error: Automation minimizes mistakes in manual stripping, such as cutting too deep or too shallow, improving overall quality control.

- Cost-Effective: By saving time and reducing errors, automatic wire stripping machines can lower labor costs and reduce material wastage, leading to a higher return on investment.

- User-Friendly Interface: Many machines are equipped with programmable settings, allowing operators to input precise dimensions for various cable types, simplifying the process.

- Safety: Automation decreases the need for operators to handle sharp tools or expose themselves to repetitive motion risks, leading to a safer work environment.

Consumables:

upper and lower blades; Drive wheels

Loại: Máy hỗ trợ thành phần SMT ngoại vi | Thẻ: automatic wire stripping cable stripping cable stripping tool wire stripper

Các Khoản mục khác trong thể loại này

-

Bàn chải mềm ESD để làm sạch chip PCB IC

-

Máy chọn và đặt máy để bàn nhỏ đơn giản chọn và đặt PCB mounter

-

Máy tuốt vỏ cáp dây tự động Dụng cụ tuốt dây điện công nghiệp

-

Máy hút ẩm công nghiệp cầm tay DR-1502L cho các nhà máy sản xuất

-

Tủ dán hàn thông minh MES Truy xuất nguồn gốc FIFO Lưu trữ FIFO Máy trộn khuấy tự động Hệ thống làm ấm lại

-

G&G Cân cân điện tử JJ224BC có chứng chỉ hiệu chuẩn

-

Máy làm sạch siêu âm nhỏ 0.7L 1L

-

Máy hàn thanh nóng HH5331 Hàn FPC PCB LED

Biểu mẫu Yêu cầu

Bản quyền 2008-2025 Thâm Quyến FS thiết bị CO.,LTD Tất cả các quyền được bảo lưu.