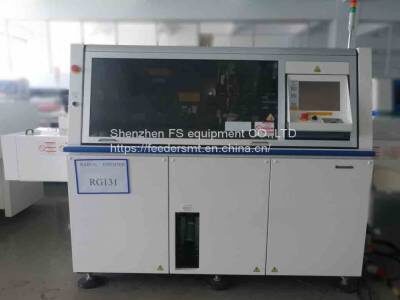

| Модель машины: |

NM-EJR1A/NM-EJR2A |

| Тип машины: |

Радиальное введение RL131 |

| Макс. скорость: |

0.17с/компонент |

| Размер компонентов приложения: |

Шаг 2,5/5,0 мм, hn=макс.21мм, D= макс.13 мм |

| Диаметры печатных плат(Д*В): |

50 x 50 мм до 508 x 381мм |

| Источник электричества: |

3-фаза AC200В,3.5Ква |

| Клеймо: |

Панасоник |

| Пневматический источник: |

0.5Мпа,80л/мин(А.Н.Р.) |

| Размер машины(Д*Ш*В): |

3200 x 2417 х 1575мм |

| Вес брутто: |

2350 КГ |

| Время упреждения: |

10 будни |

| Способ отгрузки: |

По морю |

| Условия оплаты: |

Т/Т |

|

|

Спецификация:

Размер печатной платы (миллиметр) L 50 × Ш 50〜Л 508 × Вт 381

Скорость подключения*1 0.25 с/точка~0,6 с/точка

Количество установленных компонентов 40 80 (в режиме соединения), 40 + 40 (в режиме обмена)

Шаг компонента объекта 2.5 миллиметр, 5.0 миллиметр, 7.5 миллиметр, 10.0 миллиметр

Обзор продукта: Panasonic RL131 Радиальный станок для производства свинцовых компонентов,

Размер основания (миллиметр) L 50 × Ш 50〜Л 508 × Вт 381,

Скорость подключения*1 0.25 с/точка~0,6 с/точка,

Количество монтируемых компонентов 40 80 (в режиме соединения), 40+40 (в режиме обмена, Расстояние между целевыми компонентами равно 2.5 миллиметр, 5.0 миллиметр, 7.5 миллиметр, 10.0 миллиметр

Функции:

Высокая скорость и высокая эффективность

V-образные режущие ножки могут увеличить скорость вставки

Штекерная вставка 2,5/5,0 мм автоматическая смена, опционально 7,5/10,0 мм

Используйте направляющий штифт для введения и увеличения скорости введения

Большое количество станций, до 80 различные компоненты или 32 Крупногабаритные компоненты

80 Станции имеют двойные подающие станции, с режимом подготовки материала и режимом переключения

Автоматическая подача

Как передний, так и задний сенсорные экраны машины могут управлять оборудованием, который прост в использовании

С двумя печатными платами, эффективно сокращают время передачи

Встроенная многоязычная словесная операционная система

Высокая производительность

1 Используйте метод последовательности поставки компонентов для увеличения рабочей скорости.

В дополнение к максимальной скорости ввода 0.17 секунды/пункт, так как блок подачи компонентов неподвижен, необходимо учитывать только расстояние перемещения двухкоординатного стола.

.Данные ЧПУ могут снизить потерю скорости и обеспечить высокоскоростную вставку радиальных деталей.

.Детали также могут быть заменены в процессе эксплуатации, что может снизить потери оборудования при поставке запчастей.

2 Подразделение блока поставки компонентов 2 Может реализовывать несколько режимов работы.

.В рабочем режиме, Используйте четыре устройства для работы в режиме Биржа в качестве режима работы, Отказ от электронных компонентов.

. Повышение производительности за счет сокращения ситуации и уменьшения потерь электронных компонентов.

Высокая скорость вставки и высокая надежность

1Высокая надежность высокоскоростных пластин и радиальных компонентов

.0.17 Высокоскоростной подключаемый модуль s/point реализуется с помощью режима ведущего патрона электронного компонента и сервопривода переменного тока толкателя вверх и вниз.

.Имеет функцию коррекции изгиба подводящих проводов электронных компонентов, а V-образный разрез подводящей проволоки обеспечивает стабильную вставку.

2 Простое приготовление, не нужно останавливаться.

.Путем модификации ленточного блока электронных компонентов, Стойки 2,5 мм и 5,0 мм можно использовать совместно.

.Сервопривод главного вала переменного тока, Простота в обслуживании.

|

Модель радиального станка

|

Скорость/с/чип

|

Размеры печатной платы

|

Применимые компоненты

|

Клеймо

|

| РЛ131 NM-EJR1A |

0.17 |

От Д50 мм x Ш50 мм до Д508 мм x Ш381 мм |

Шаг 2,5,5,0 мм, hn = макс.21 мм, D = макс.13 мм |

Панасоник |

| РГ131 NM-EJR3A |

0.25~0.6 |

От Д50 мм x Ш50 мм до Д508 мм x Ш381 мм |

Шаг 2,5,5,0 мм,7.5мм и 10 мм(выбор) |

Панасоник |

| РХС2Б НМ−РА20А |

0.17 |

От Д50 мм x Ш50 мм до Д508 мм x Ш381 мм |

Шаг 2,5,5,0 мм |

Панасоник |

| РГСГ НМ-РБ00А |

0.25 |

Д50 мм x Ш50 мм до Д330 мм x Ш250 мм |

Шаг 2,5 мм,5.0миллиметр |

Панасоник |

Совместная работа с FS, Мы можем предоставить полную линию SMT для вставки THT PTH для всех клиентов по сборке печатных плат по всему миру. Мы можем предоставить полный спектр услуг по проектированию, снабжение, монтаж к пуско-наладочным работам ; Для получения дополнительной информации.

-400x300.jpg)