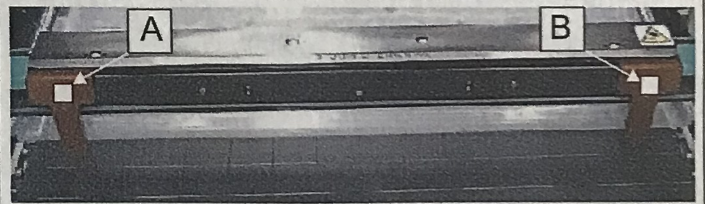

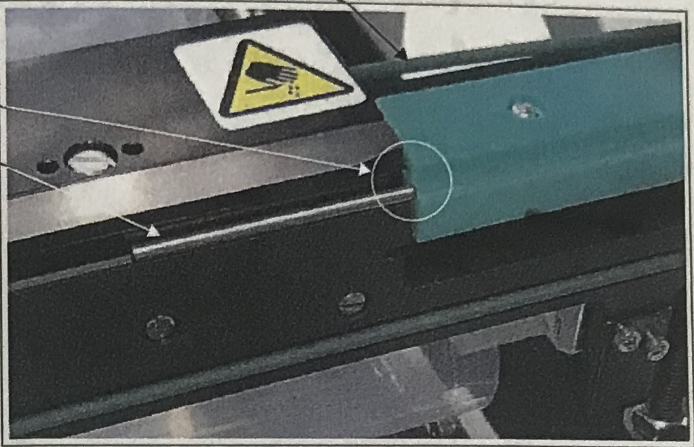

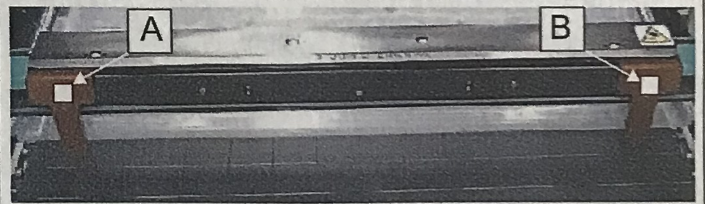

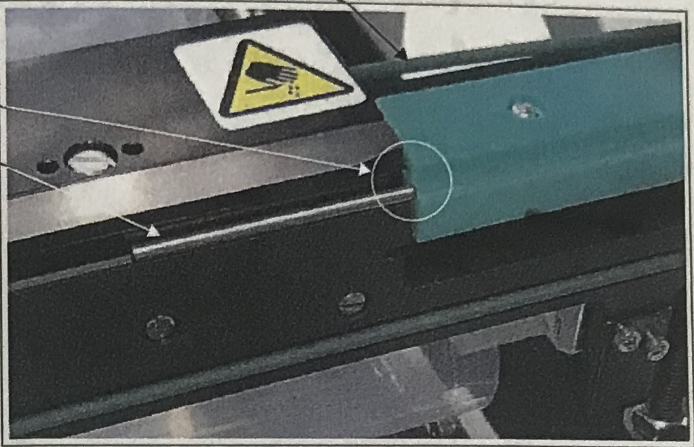

The height of the rail relative to the table in a DEK printer can significantly impact the printing of solder paste on boards. The rail height determines the separation distance between the stencil and the circuit board. We have to use DEK Calibration 193177 RAIL TO TABLE TOOL KIT for the belts.

This distance is crucial for achieving the desired solder paste deposition.

If the rail is too high, there might be insufficient pressure between the stencil and the board, resulting in incomplete or uneven solder paste application.

On the other hand, if the rail is too low, it can lead to excessive pressure, causing smearing or misalignment of the solder paste.

Therefore, maintaining the optimal height of the rail is essential for ensuring accurate and consistent solder paste printing,

which, in turn, contributes to the overall quality and reliability of the electronic components on the printed circuit boards.

Adjusting and calibrating the rail height appropriately is a key aspect of the setup and maintenance of DEK printers in electronics manufacturing.