| Machine Model: |

NM-EJR1A/NM-EJR2A |

| Machine Type: |

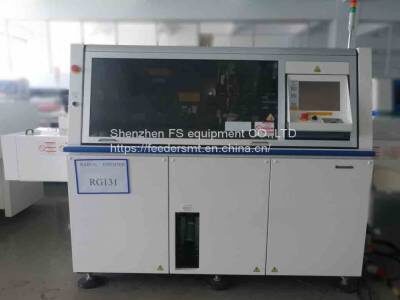

Radial insertion RL131 |

| Max. speed: |

0.17s/component |

| Application components size: |

Pitch 2.5/5.0mm, Hn=Max.21mm, D= Max.13mm |

| PCB diameters(L*W): |

50 x 50 mm to 508 x 381mm |

| Electric source: |

3-phase AC200V,3.5kVA |

| Brand: |

Panasonic |

| Pneumatic source: |

0.5MPa,80L/min(A.N.R) |

| Machine Size(L*W*H): |

3200 x 2417 x 1575mm |

| Gross Weight: |

2350 KG |

| Lead Time: |

10 working days |

| Shipment way: |

By sea |

| Payment Terms: |

T/T |

|

|

Specification:

PCB size (mm) L 50 × W 50〜L 508 × W 381

Plug-in speed*1 0.25 s/point~0.6 s/point

Number of components installed 40 80 (in connection mode), 40 + 40 (in exchange mode)

Object component pitch 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm

Product Overview: Panasonic RL131 radial lead component machine,

Substrate size (mm) L 50 × W 50〜L 508 × W 381,

Plug-in speed*1 0.25 s/point~0.6 s/point,

The number of components mounted 40 80 (in connection mode), 40+40 (in exchange mode, the distance between target components is 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm

Features:

High speed and high efficiency

V-shaped cutting feet can increase the insertion speed

Plug-insert 2.5/5.0mm automatic change, optional 7.5/10.0mm

Use a guide pin to introduce and increase the speed of insertion

A large number of stations, up to 80 different components or 32 large components

80 stations have dual feed stations, with material preparation mode and switch mode

Automatic feeding

Both the front and back touch screens of the machine can operate the equipment, which is easy to use

With two PCBs, effectively reduce the transmission time

Built-in multilingual word operating system

High productivity

1 Use the component supply sequence method to increase the operating rate.

In addition to the maximum insertion speed of 0.17 seconds/point, since the component supply unit is fixed, only the movement distance of the XY table needs to be considered.

.NC data can reduce speed loss and realize high-speed insertion of radial parts.

.Parts can also be replaced during operation, which can reduce the loss of equipment when parts are provided.

2 The division of component supply unit 2 can realize multiple operation modes.

.In the operation mode, use four devices to work in the exchange mode as the operation mode, avoiding electronic components.

. Improve productivity by reducing the situation and reducing the loss of electronic components.

High-speed insertion and high reliability

1High reliability of high-speed inserts and radial components

.0.17 s/point high-speed plug-in is realized by the electronic component lead chuck mode and the up and down AC servo of the push rod.

.It has the function of correcting the bending of the lead wires of electronic components, and the lead wire V-cut realizes stable insertion.

2 Simple preparation, no need to stop.

.By modifying the tape unit of the electronic components, the racks of 2.5mm and 5.0mm can be shared.

.Main shaft AC servo motorization, easy maintenance.

|

Radial machine Model

|

Speed/s/chip

|

PCB dimensions

|

Applicable components

|

Brand

|

| RL131 NM-EJR1A |

0.17 |

L50mm x W50 mm to L508mm x W381mm |

Pitch 2.5,5.0mm, Hn = Max.21mm, D = Max.13mm |

Panasonic |

| RG131 NM-EJR3A |

0.25~0.6 |

L50mm x W50 mm to L508mm x W381mm |

Pitch 2.5,5.0mm,7.5mm and 10mm(option) |

Panasonic |

| RHS2B NM−RA20A |

0.17 |

L50mm x W50 mm to L508mm x W381mm |

Pitch 2.5,5.0mm |

Panasonic |

| RHSG NM-RB00A |

0.25 |

L50mm x W50 mm to L330mm x W250mm |

Pitch 2.5mm,5.0mm |

Panasonic |

Working together with FS, we are able to provide a complete SMT insertion THT PTH line for all PCB assembly customers all over the world. We can provide the complete service from design, supply, installation to commissioning ; for more information.

-400x300.jpg)