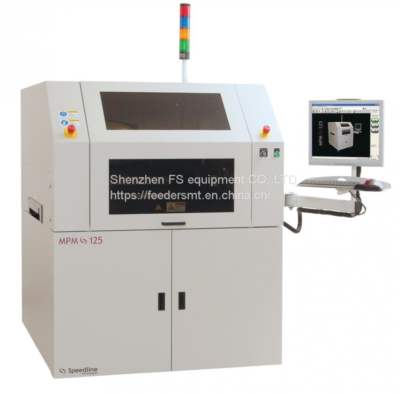

스피드라인 MPM 125 스크린 프린터

|

|

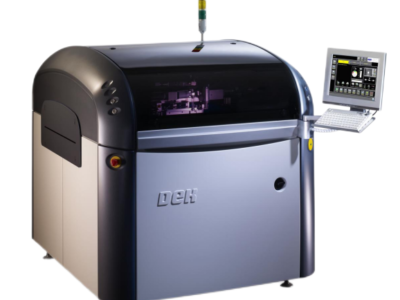

The solder paste printing machine is generally composed of plates, solder paste, embossing, circuit board transmission and other mechanisms. Its working principle is: first fix the circuit board to be printed on the printing positioning table, then the left and right scrapers of the printing machine will leak the solder paste or red glue to the corresponding pad through the stencil. The transfer table is input to the pick and place machine for automatic placement.

Technical Parameters of MPM125 automatic solder paste printing machine:

PCB substrate processing:

Board size (X×Y) 609.6mm×508mm (24″×20″)

Small board size (X×Y) 50.8mm×50.8mm (2″×2″)

Board thickness size 0.2mm (0.008″) to 5.0mm (0.20″)

Printing parameters

Printing area 609.6mm×508mm

Printing release film 0mm to 6.35mm

Printing speed is as fast as 305mm/sec

Printing pressure 0 to 22.7kg

Steel mesh size 737mm×737mm

performance

System alignment accuracy and repeatability ±12.5 microns (±0.00005″) @60, Cpk is greater than or less than 2.0*

Cycle time 13sec

전원 요구 사항 200 to 240VAC (±10%) single phase @50/60Hz, 15A

Air requirements 100psi at 4 cfm (standard operating mode) 받는 사람 18 cfm (vacuum wipe) (7 bar@5L/S to 12L/S), 12.7밀리미터 (0.5″) diameter pipe

크기: L1593×1214×1638 (밀리미터)

무게: 872킬로그램