의료 장비의 SMT를 위한 특수 SMD 부품용 맞춤형 노즐

Understanding the Role of Custom Nozzles in SMT

이 기사에서, we’ll explore the importance of custom nozzles in SMT for medical equipment and how they integrate into the broader landscape of EMS electronics manufacturing.

We know that custom nozzles are designed to handle specific tasks in the SMT manufacturing process.

They ensure that the silicone actuator tact switches are accurately placed on the PCB (인쇄 회로 기판) to achieve the performance of medical equipment.

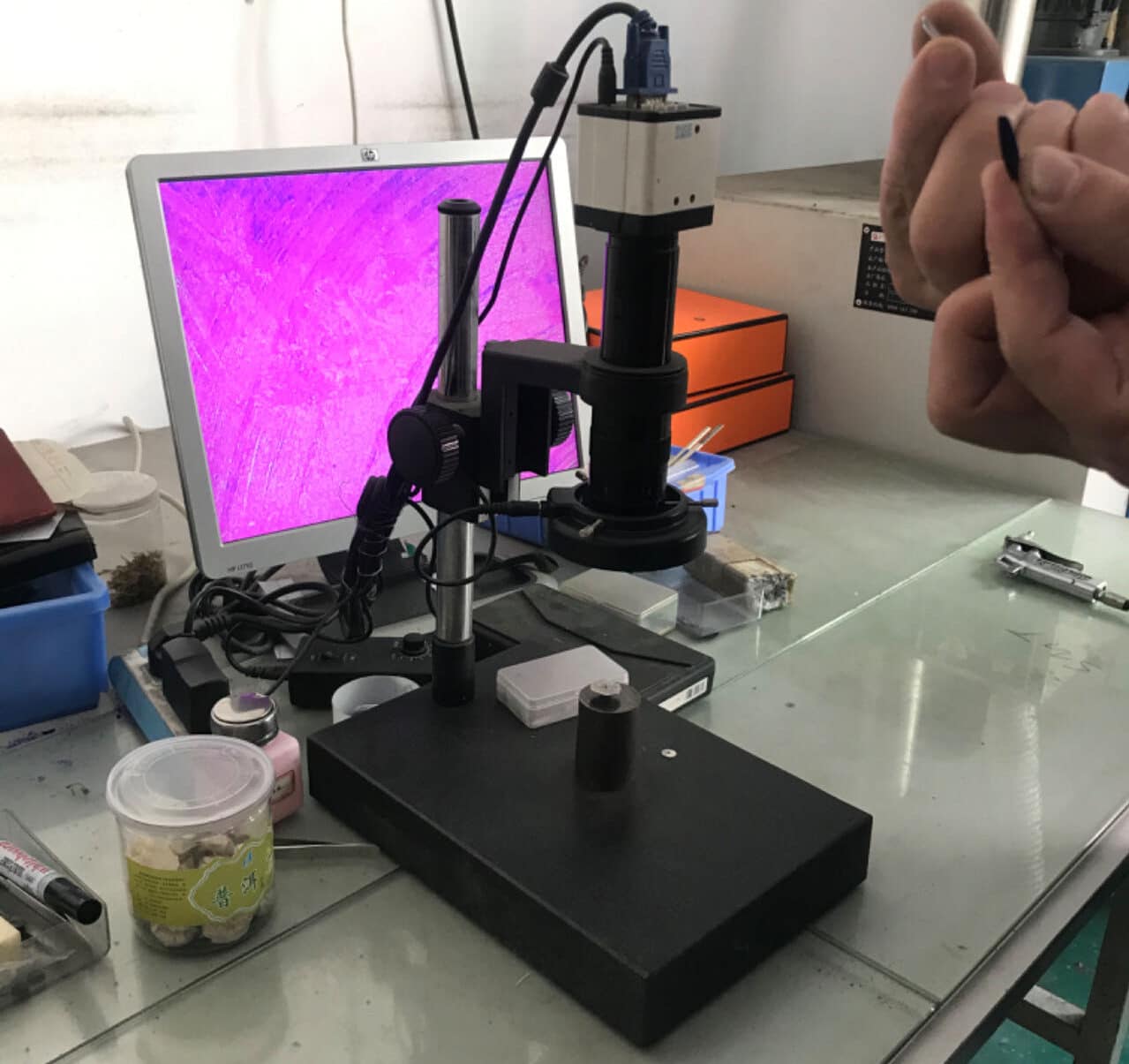

The Manufacturing Process

The production in the custom nozzle manufacturer involves various steps and technologies. Tooling machines are essential in crafting this SMT pick and place nozzles to meet specifications.

The nozzle supplier is equipped with advanced machinery & machine tools that can handle the complexity of the task.

- For suction nozzle drilling, we use advanced Italian IEMCA CNC lathe bar feeders

- Nozzle base, SWISS TYPE TSUGAMI Opposed Gang Tool CNC Lathe

- High-temperature baking machine, ceramic nozzle SMT

- Manufacturing reflector and reflective film by Film Laminating Machine

- Calibration reflector

- Laser engraving QR code

Customized Nozzles Type

For the needs of different fields, medical equipment, household appliances, televisions, refrigerators, air conditioners, washing machines, car navigation systems, automotive security, pressure sensors, and LED lighting fixtures.

Customized nozzles can be made into ceramic nozzles and alloy nozzles.

Advantages and Disadvantages of Customized Nozzles

Ceramic nozzles: The main raw materials of ceramic nozzles are zirconium oxide, alumina ceramics, 등.

1. SMT nozzles will not have the problem of whitening

2. The service life can be up to twice that of diamond steel

3. No static electricity will be generated during the production process of high-speed placement machines

4. Stronger wear resistance than alloy nozzles

5. Relatively higher price

3. Widely used in Panasonic, 야마하, I-펄스, 삼성, 후지산, Siemens ASM, 쥬키, 히타치, and Universal placement equipment.

Advantages and Disadvantages of Alloy Nozzles

The main raw materials of alloy nozzles are tungsten steel or POM.

1. SMT nozzles may turn white

2. Shorter service life than ceramics

3. Alloy nozzles are more wear-resistant

5. Relatively affordable

3. Widely used in Panasonic, 야마하, 삼성, 후지산, and JUKI SMT equipment