高品質の供給品で製造SMTプロセスを簡素化

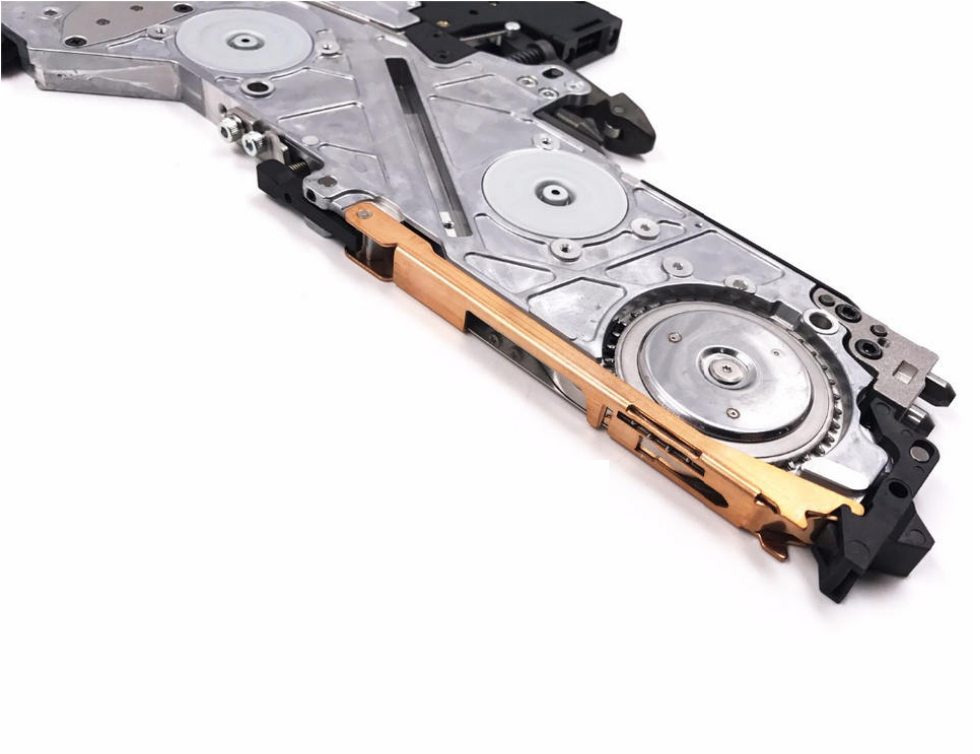

ZSフィーダーは、ヤマハのピックアンドプレースマシンで使用される最も人気のあるフィーダーの1つです。, そしてそれは4mmから72mmまで及ぶ異なったサイズで来ます. この記事の内容, ZSフィーダーの特徴と利点、およびそのさまざまなサイズについて説明します. ヤマハはエレクトロニクス業界で有名なブランドです, 電子機器の製造プロセスを支援する高品質のピックアンドプレースマシンで知られています.

ZSフィーダーは、幅広い部品に対応するように設計されたテープフィーダーです, さまざまな製造プロセスに用途が広く便利になります. ヤマハの高効率モジュラーと互換性があり、さまざまな種類のコンポーネントを処理できます, ・・抵抗を含む, コンデンサー, および集積回路. ZSフィーダーには7つの異なるサイズがあります, 4mm KLJ-MCN00-000,8mm KLJ-MC100-000,12mm 16mm KLJ-MC200-000,24mm KLJ-MC400-000,32mm KLJ-MC500-000,44mm KLJ-MC600-000,56mm KLJ-MC700-000,72mm KLJ-MC800-000,88mm KLJ-MC900-000を含む.

ZSフィーダーの主な利点の1つは、さまざまなサイズや形状のコンポーネントを処理できることです, 電子機器メーカーにとって不可欠なツールに. フィーダーの汎用性は、利用可能なさまざまなサイズによって強化されます, これにより、さまざまな形状やサイズのコンポーネントを供給することができます. フィーダーの設計は、さまざまな高さと幅のコンポーネントを処理できるように設計されています, 製造プロセス中にコンポーネントが正しく配置されていることを確認する.

また、ZSフィーダーは堅牢な構造を誇り、高速製造プロセスでの使用に適しています. フィーダーは、製造プロセスの厳しさに耐えることができる高品質の素材で作られています, それが長持ちし、耐久であることを保証する. フィーダーの設計により、操作も容易です, 初心者と経験豊富なオペレーターの両方にとって理想的なツールになります.

ZSフィーダーの主な特徴の1つは、製造プロセス中のコンポーネントの供給精度です. フィーダーは、コンポーネントがプリント回路基板上に正確に配置されるように設計されています, 製造工程でのエラーリスクを低減. フィーダーの設計により、コンポーネントが正確にピックアップされ、配置されます, 完成品が高品質であることを確認する.

ZSフィーダーのもう一つの利点は、その速度です, 生産量を大幅に増やすことが可能. フィーダーは一度に複数のコンポーネントを処理できます, 製造プロセスの迅速化と効率化を実現. フィーダーの設計により、コンポーネントが正確かつ迅速にピックアップされ、配置されます, 製造プロセスの高速化.

ZSフィーダーは、操作とメンテナンスを容易にするユーザーフレンドリーなデザインも誇っています. フィーダーのデザインは、コンポーネントのロードとアンロードが容易なものです, 製造プロセスが中断されないようにする. フィーダーは、清掃とメンテナンスも簡単です, 製造工程での故障リスクを低減.

おわりに, ZSフィーダーは、電子機器メーカーにとって不可欠なツールです, その汎用性のおかげで, 精度, とスピード. フィーダーの設計により、さまざまなサイズや形状のさまざまなコンポーネントを処理できます, さまざまな製造プロセスに対応する汎用性の高いツールに. フィーダーの精度により、コンポーネントがプリント回路基板に正しく配置されます, 製造工程でのエラーリスクを低減. フィーダーの速度により、製造プロセスがより速く、より効率的になります, 生産量の大幅な増加. さまざまなサイズが利用可能, 電子機器メーカーは、製造ニーズに合ったフィーダーサイズを選択できます, 完成品が高品質であることを確認する.