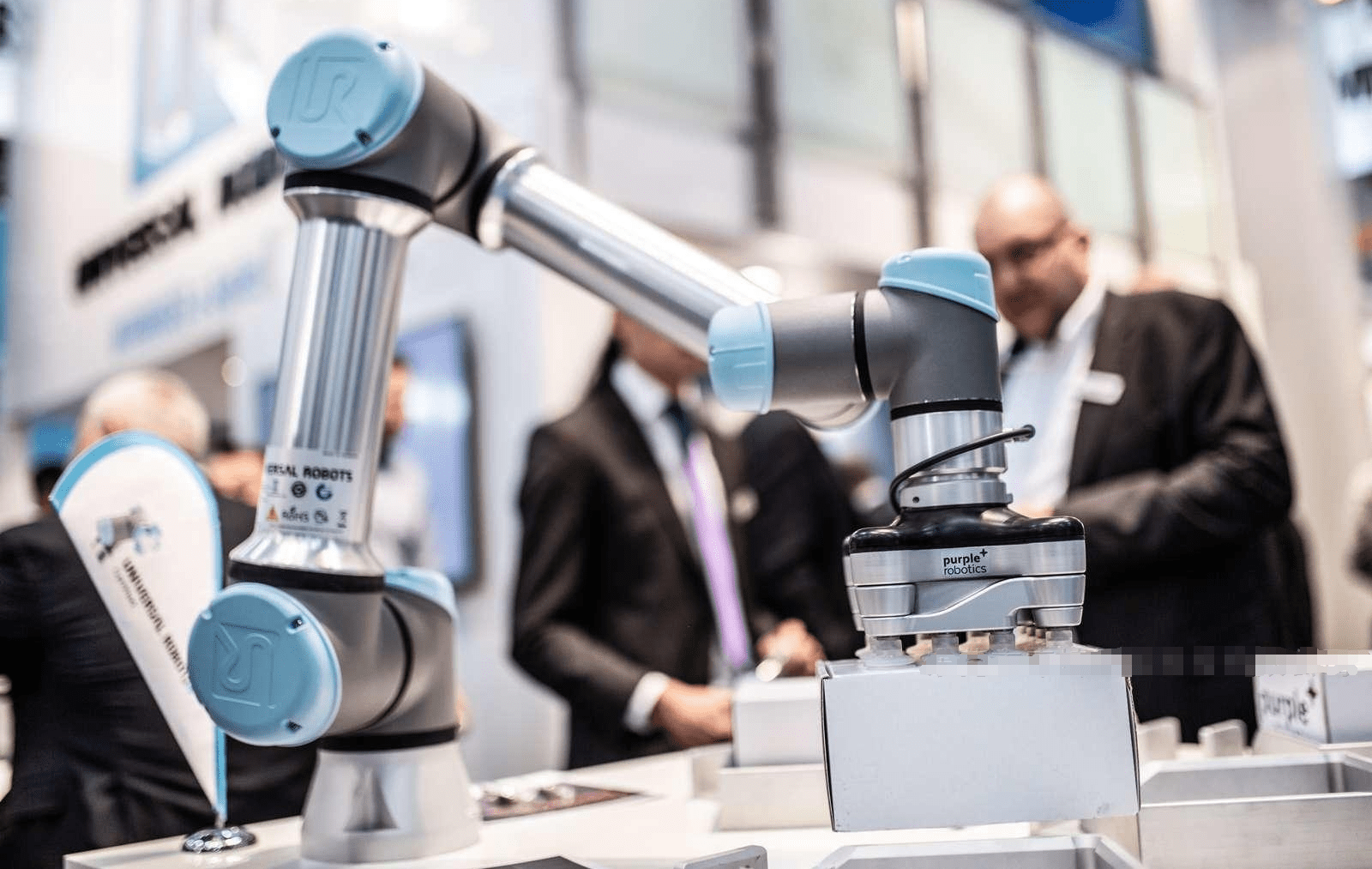

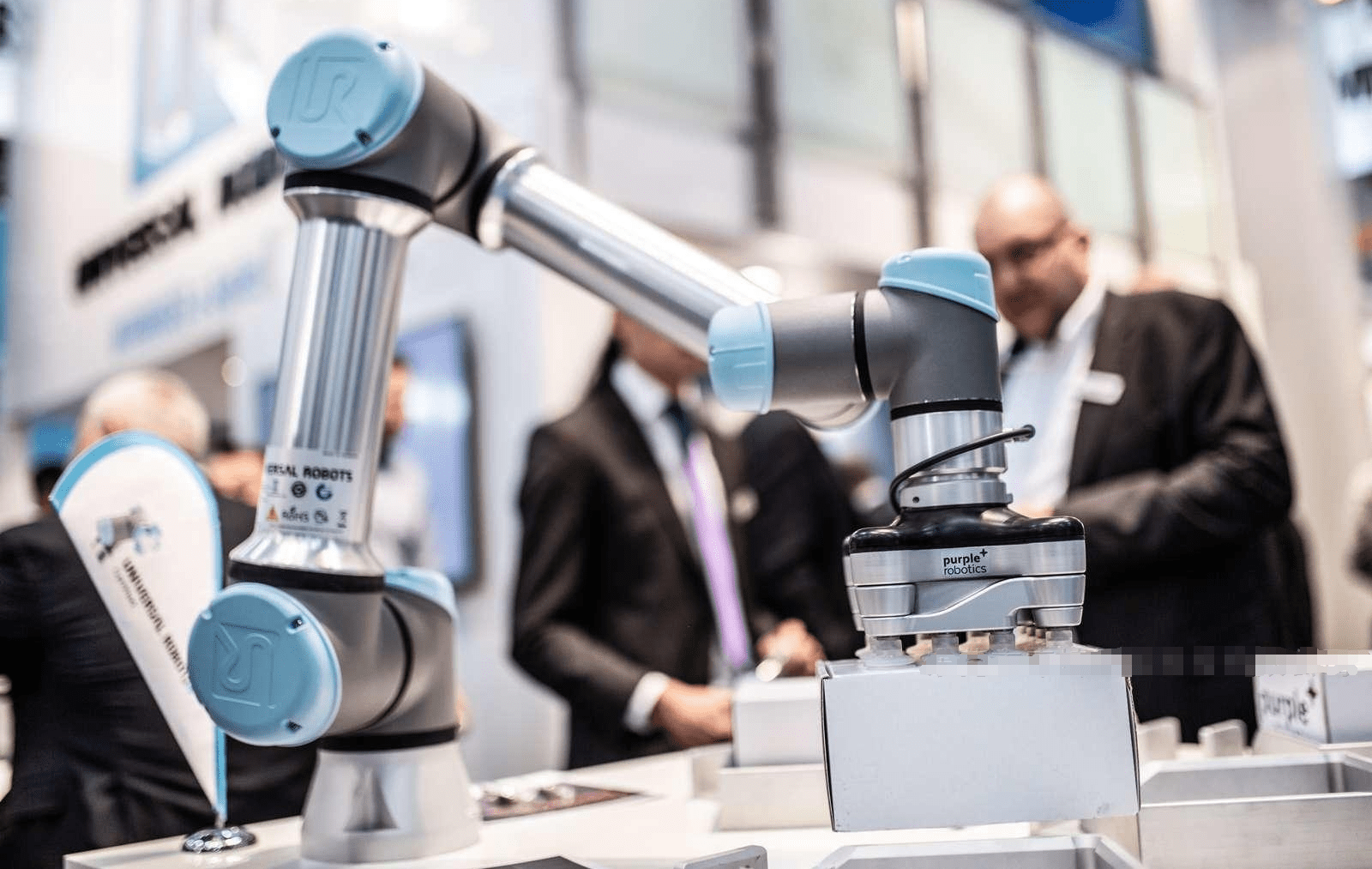

In today’s fast-paced world of electronics manufacturing, the PCB (Printed Circuit Board) assembly industry has seen a significant transformation, primarily owing to the extensive use of robots. These mechanical marvels have brought about a revolution in the way PCBs are assembled, enhancing precision, efficiency, and speed while reducing human error. This article delves into the various aspects of how robots are widely used in the PCB assembly industry.

The Role of Robots in PCB Assembly

PCB handling Robot Process

PCB-handling robots are known for their exceptional precision and accuracy. They can consistently pick and place components on the PCB with high repeatability, reducing the chances of errors in assembly.

PCB assembly Robot -Automated Component Placement

One of the key areas where robots excel in PCB assembly is automated component placement. These machines can accurately and rapidly place components on high-density PCBs, improving the overall efficiency of the assembly process. The great precision offered by robots ensures that each delicate and tiny component is placed in the right location, As well as the small pitch between these components. The PCB assembly robot equipment reduces the chances of errors.

PCB soldering Robot –Precision Soldering

Robots are also extensively used in soldering processes, which require a high level of precision. They can apply solder to the right joints consistently, ensuring strong and reliable connections between components. This level of precision is often challenging to achieve manually.

PCB Inspection and Testing Robot –Quality Control and Inspection

Robots equipped with advanced vision systems play a crucial role in quality control and inspection. Such as X-Ray, SPI equipment, and the camera-mounted robot. They can detect defects or anomalies in real time, allowing for immediate corrective actions. This enhances the overall quality of PCB assembly.

Benefits of Using Robot

Speed and efficiency

The robot works tirelessly around the clock without fatigue, which significantly improves the speed and efficiency of the PCB assembly process. Such fast and innovative electronics manufacturer will be at the forefront of their competitors.

Reduction in Human Error

Human errors are a significant concern in manual assembly processes. Robots, on the other hand, are not susceptible to the same issues, resulting in a substantial reduction in assembly errors.

Flexibility and Versatility in PCB Assembly

Automatic Robot equipment is generic. They can adapt to different assembly requirements. They can handle various and shrinking PCB sizes and shapes and are widely applicable to electronic PCB manufacturing.

Challenges in Implementing Robots

Cost Considerations

While the benefits of using robots in PCB assembly are evident, the initial investment in robotics technology can be substantial. Companies must weigh the cost against the long-term gains.

Skilled Labor vs. Robotics

Some argue that skilled human labor is essential for certain intricate assembly tasks. Finding the right balance between skilled human workers and robots is a challenge.

Future of Robotics in PCB Assembly

The future of robotics in the PCB assembly industry is promising. As technology advances, robots are likely to become even more sophisticated and affordable. With robots adopting all aspects of PCB assembly, The industry will be more automated.

Rapidly Adopting Different Robots

Are you ready to take your manufacturing processes to the next level? It’s time to embrace the future with the rapid adoption of diverse robot solutions. Whether you’re in electronics manufacturing, healthcare, logistics, or any industry, robots can transform the way you operate.

Don’t wait; seize the opportunity to boost efficiency, precision, and competitiveness. Invest in robotics to streamline your processes, reduce costs, and stay ahead of the curve. The time is now.

Contact us to explore how robots can revolutionize your industry. Let’s embark on this exciting journey together and unlock the full potential of automation. Act today for a brighter, more efficient tomorrow.”

FAQs

- Are robots used in all PCB assembly processes?

Robots are used in all stages of PCB assembly, but not necessarily in every process. Their use depends on the specific needs of the manufacturer.

- Can robots completely replace human workers in PCB assembly?

While robots are highly efficient, some assembly tasks may still require human intervention, especially for intricate work that demands a high level of skill.

- How do robots contribute to reducing costs in PCB assembly?

Robots reduce costs by improving efficiency, reducing errors, and increasing the speed of assembly. However, the initial investment in robotics technology must be considered.

- What is the impact of robotics on the quality of PCB assembly?

Robots enhance quality control and inspection, resulting in a higher overall quality of PCB assembly.

- How can a company get started with robotics in PCB assembly?

To get started with robotics in PCB assembly, companies should research suitable robotic solutions, consider their specific assembly needs, and evaluate the long-term benefits of automation.