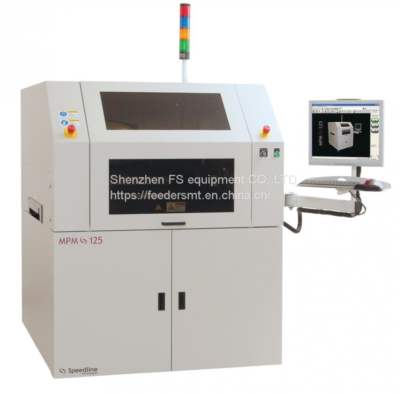

| Numéro de modèle: |

Speedline MPM 125 |

| Zone d’impression: |

609.6mm×508mm |

| Impression de films antiadhésifs: |

0mm à 6,35 mm |

| Vitesse d’impression: |

305mm/sec |

| Pression d’impression: |

0 à 22,7 kg |

| Maille d’acier: |

737mm×737mm |

| Taille: |

L1593×1214×1638 (mm) |

| Poids: |

872Kg |

|

|

La machine d’impression de pâte à souder est généralement composée de plaques, pâte à souder, embossage, Transmission par carte de circuit imprimé et autres mécanismes. Son principe de fonctionnement est le suivant :: Fixez d’abord le circuit imprimé à imprimer sur la table de positionnement d’impression, Ensuite, les grattoirs gauche et droit de la machine d’impression laisseront échapper la pâte à souder ou la colle rouge sur le tampon correspondant à travers le pochoir. La table de transfert est entrée dans la machine de prélèvement et de placement pour un placement automatique.

Paramètres techniques de la machine d’impression automatique de pâte à souder MPM125:

Traitement des substrats de PCB:

Taille de la planche (X×Y) 609.6mm×508mm (24« ×20 »)

Petite taille de planche (X×Y) 50.8mm×50,8 mm (2« ×2 »)

Épaisseur de la planche 0,2 mm (0.008″) à 5,0 mm (0.20″)

Paramètres d’impression

Zone d’impression 609,6 mm×508 mm

Film antiadhésif d’impression 0 mm à 6,35 mm

La vitesse d’impression est aussi rapide que 305 mm/s

Pression d’impression 0 à 22,7 kg

Taille du treillis d’acier 737mm×737mm

performance

Précision et répétabilité de l’alignement du système ±12,5 microns (±0,00005") @60, Cpk est supérieur ou inférieur à 2.0*

Temps de cycle 13sec

Exigences en matière d’alimentation 200 à 240VAC (±10 %) monophasé @50/60Hz, 15Un

Besoins en air 100 psi à 4 Cfm (Mode de fonctionnement standard) À 18 Cfm (Essuyage sous vide) (7 bar@5L/S à 12L/S), 12.7mm (0.5″) diamètre du tuyau

Taille: L1593×1214×1638 (mm)

Poids: 872Kg