| Numéro de pièce: |

KCH-MS30-001 |

| Qualité(g/㎡): |

42 |

| Épaisseur(mm): |

0.2 |

| Traction(N): |

X:85 Y:24 |

| Électrification par friction(Kv): |

Sous 0.2 |

| Matériel: |

50% cellulose,45% polyester |

| Rouleau de nettoyage disponible pour machine Include: |

YCP10-YSP |

| Tube: |

Papier ou plastique |

| Delai: |

3-5 jours ouvrables |

|

|

Utilisé pour la machine d’impression Yamaha modèle YCP10 YSP

SPÉCIFICATION

. Le matériau peut être facultatif:

(1)50% cellulose,45% polyester

(2)coton 100%

(3)PP 100%

« Le standard est le premier.

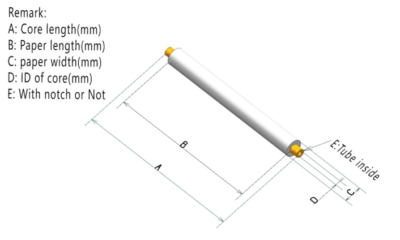

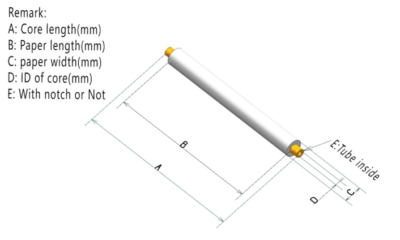

. Taille du noyau du tube: 25mm 26 mm ou plus

. Longueur du tube: 360mm 420mm 440mm ou plus

. Longueur totale du papier: 10m 25m ou mor

Il est utilisé pour le nettoyage de surfaces de haut niveau. Il s’agit d’un papier essuyé spécial pour l’impression SMT de cartes de circuits imprimés dans l’industrie électronique. Il peut éliminer efficacement l’excès de pâte à souder et de colle rouge attachés au pochoir de la machine d’impression et aux circuits imprimés, et gardez les circuits électroniques impeccables. Réduire considérablement le taux de rebut, améliorer considérablement l’efficacité de la production et la qualité des produits.

FS ne fournit pas seulement du papier rouleau de nettoyage pour l’imprimante Yamaha Modèle YCP10 YSP. Ainsi que la marque DEK,PANASONIC,MPM,DESEN,EKRA,Machine de sérigraphie à souder ESE.

Fonctionnalités:

(1) Solide et durable, avec une absorption élevée d’eau et d’huile, mou, Performances anti-poussière et antistatiques.

(2) La matière est douce, ne produit pas de rayures sur la surface de l’objet de nettoyage, et n’endommage pas la surface de l’objet.

(3) Il peut être utilisé avec une solution de nettoyage.

(4) Super capacité d’absorption de liquide, plus de quatre fois plus rapides que les lingettes en coton ordinaires.

(5) Élimine efficacement les taches d’eau et d’huile sans utiliser d’adhésifs chimiques.

(6) Parce qu’il est produit dans une salle blanche, Il évite l’inclusion d’impuretés dans le papier d’essuyage, ce qui peut réduire l’apparition de défauts d’impression dus aux impuretés entraînées dans l’essuyage du pochoir pendant le processus d’impression.

(7) Il peut être associé à un emballage antistatique pour répondre aux exigences antistatiques strictes des produits électroniques.