| Kit-Nummer: |

N610095856AB |

| Name des Kits: |

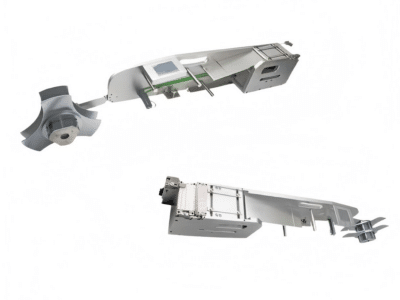

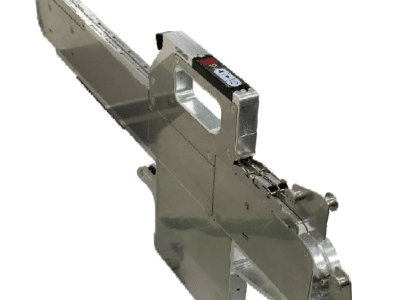

multifunctional transfer unit |

| Benutzend: |

Transfer flux gel for BGA CSP process |

| Elektronisch oder mechanisch: |

Elektronisch |

| Vorlaufzeit: |

Lager |

| Versandart: |

Mit dem Flugzeug |

| Zahlungsbedingungen: |

T/T |

|

|

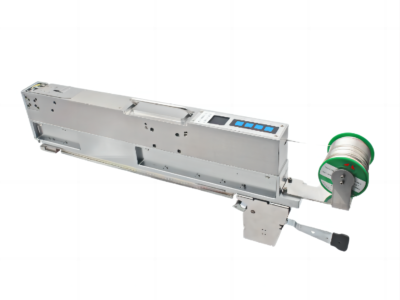

POP SMT Feeder for PCB Assembly – Features and Technical Parameters

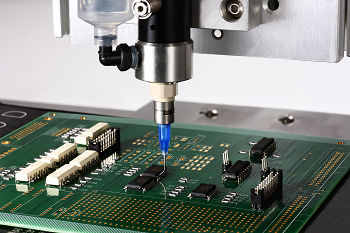

Introduction to POP SMT Feeder and its Functionality

The POP SMT feeder is an indispensable tool for PCB assembly that features a multifunctional transfer unit N720SA000E02 that can be installed to various Panasonic pick and place machines, including the NM-EJM3D, NPM-TT, NM-EJM2D, NPM-W, NM-EJM7D, NPM-W2, NM-EJM9B, NPM (Englisch), NM-EJM1D, NPM-D, NM-EJM5D, NPM-D2, NM-EJM6D, and NPM-D3. A powerful and versatile tool for PCB assembly. With its advanced capabilities, the Multi-Transfer Unit POP Feeder can handle the most complex PCB assembly tasks. Highly effective in applying Flux-gel on components during the mounting of BGA with CSP technology, which is a chip scale package technology that is highly effective in enhancing the reliability of electronic components.

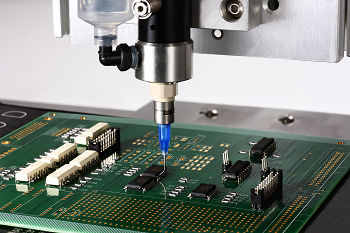

Application of Flux-Gel in BGA and CSP Technology with POP SMT Feeder

In situations where fine pitch components cannot be mounted on the solder paste but only with flux gel, the POP SMT feeder prevents the backside components from falling off during reflow soldering. This helps to strengthen the adhesion of BGA and CSP, ensuring that the solder joints remain intact during thermal cycle testing. This is especially important for handheld devices such as mobile phones, which are subjected to severe drop and tumble tests, as many BGA solder joints are almost unbearable without the support of underfill.

The underfill material used in the POP SMT feeder usually consists of epoxy, which uses the principle of capillary action to apply Epoxy to the edge of the wafer to penetrate into the bottom of the flip chip or BGA. The material is then heated to cure, which effectively improves the mechanical strength of the solder joints and increases the service life of the wafer. Als Ergebnis, underfill is commonly used in the circuit board design of handheld devices such as mobile phones to enhance the reliability of electronic components.

The Advantages of Underfill Material in Strengthening the Adhesion of BGA and CSP in PCB Assembly.

In addition to its advanced transfer unit, the POP SMT feeder also features a host of other impressive technical parameters that make it highly effective in PCB assembly. Zum Beispiel, it has a transfer speed of 0.5 seconds per shot, which enables it to complete a large number of PCB assembly tasks within a short period. The feeder is also equipped with a large capacity, with a maximum load capacity of up to 100 Leiterplatten, which ensures that you can complete your PCB assembly tasks quickly and efficiently.

The POP SMT feeder is also designed for ease of use, featuring a user-friendly interface that allows you to control the various functions of the feeder with ease. The feeder is also highly versatile and can be used with a wide range of PCB types, including single-sided, double-sided, and multi-layered PCBs. Whether you are working on a small-scale PCB assembly task or a large-scale project, the POP SMT feeder has got you covered.

In conclusion, the POP SMT feeder is an essential tool for PCB assembly that offers a wide range of advanced features and technical parameters that make it highly effective in enhancing the reliability of electronic components. Whether you are working on handheld devices such as mobile phones or other PCB types, the POP SMT feeder is a must-have tool that will help you complete your projects quickly and efficiently. Get yours today and experience the power of the POP SMT feeder for yourself.

Technical Parameter

- Funktion: Transfer unit for applying Flux-gel on components during the mounting of BGA with CSP technology

- Funktionen: Prevents backside components from falling off during reflow soldering, strengthens the adhesion of BGA and CSP

- Material: High-quality and durable materials for long-lasting use

- Kompatibilität: Suitable for use with a wide range of substrates and electronic components