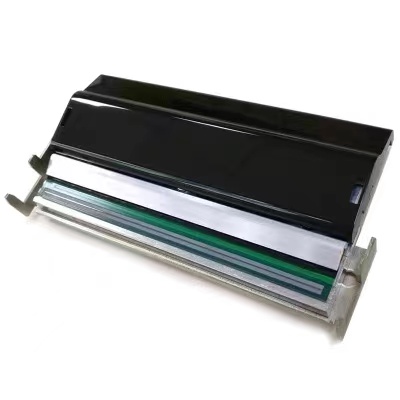

| Modellnummer: |

G41400M G79056-1M G41401M |

| Anwendung: |

Zebra Lable printer head of Z4M S4M Z4M Plus |

| Print width: |

4.09"(104Mm) |

| Auflösung: |

200 dpi 203 DPI 300 DPI |

| Paket: |

One print head |

| Vorlaufzeit: |

Lager |

|

|

Used for Zebra label Printer: Z4M S4M Z4M Plus

Auflösung:200 dpi 203 DPI 300 DPI

Printing head number:G41400M G79056-1M G41401M

Print width:4.09″(104Mm)

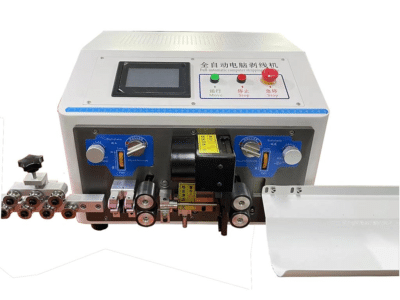

Daily maintenance of barcode printer:

After printing one roll of ribbon, clean the barcode print head. This maintains print quality and extends the life of the printhead. The specific operations are as follows:

.Print head cleaning

Turn off the power, flip the print head up, and remove the ribbon and label stock. Use a cotton swab or a cotton wipe soaked in a little print head cleaning solution to gently wipe until clean. Finally, wipe again with a dry cotton swab.

. Cleaning of the rollers

Clean the roller with a cotton wipe or cotton swab soaked in a little 75% alcohol. The method is to wipe the roller with one hand and rotate the roller with the other hand, and then dry it after it is clean.

Appeal two maintenance at least once every 3 Tage. If the printer is used frequently, use it once a day.

.Cleaning of the drive train and cleaning of the inside of the case

Because the general label paper is self-adhesive, it is easy to stand on the drive shaft and channel, and dust will directly affect the printer effect. So it needs to be done once a week. The method is to use a cotton swab or cotton wipe soaked in alcohol to wipe the surface of each shaft and channel of the transmission and the dust in the chassis. Dry after cleaning.

. Sensor cleaning

The sensor includes the ribbon sensor and the label sensor, and its location is shown in the manual. Allgemein, it is cleaned once a month to 3 Monate. The method is to blow the dust on the sensor with a blower device (suction ball)