Before analyzing the error, we need to understand the application and principle of stepper motor drive.

1. SMT machine‘s Principle of Stepper Motor Drivers

A stepper motor driver converts digital signals from the Surface mount machine’s control system into electrical pulses that drive the stepper motor. These pulses dictate the direction, speed, and position of the motor shaft.

2. Accessories and Components of a Stepper Motor Driver of Machines in manufacturing

Controller: Receives commands from the main control system of the pick and place machine or Wave solder machine and generates appropriate pulse sequences.

Driver Circuit: Amplifies the pulses from the controller to a level suitable for the motor.

Power Supply: Provides for automated machining of the necessary electrical power for the motor and the driver circuit.

Feedback System: Monitors the position and movement of the motor to ensure the SMT line machine or soldering’s accuracy.

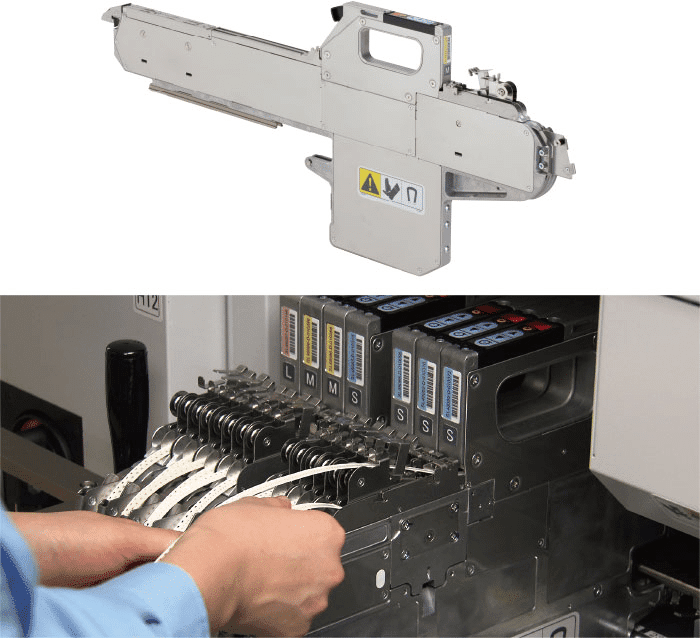

3. What function works in SMT Pick and Place Machine and 3D printer PCB

Pulse Generation: The control system of the pick and place machine sends a series of digital pulses to the stepper motor driver. Each pulse represents a step the motor should take.

Pulse Amplification and Distribution: The driver amplifies these pulses and distributes them to the appropriate coils in the stepper motor, causing the motor to move in precise increments.

Direction Control: The direction of the pulses determines the rotation direction of the stepper motor. For instance, a clockwise pulse sequence will cause the motor to rotate clockwise.

Microstepping: Modern stepper motor drivers support microstepping, which allows the motor to move in smaller steps than its standard step size, providing smoother and more precise motion. It is important in SMT machine electronics manufacturing to accurately place tiny components on a PCB(Printed circuit board).

Speed Control: The frequency of the pulses controls the speed of the motor. Faster pulse rates result in higher motor speeds, while slower pulse rates decrease the speed.

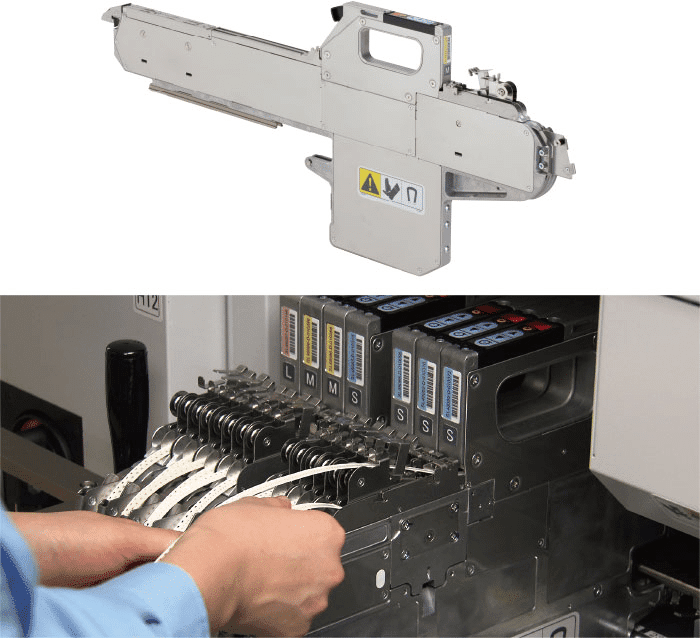

4. Application in SMT Pick and Place Machine.

X-Y-axis Movement: The stepper motor drivers control the X-axis and Y-axis movements of the placement head, allowing it to move to the correct coordinates position on the PCB where the PCB board components need to be placed.

Z-Axis Movement: SMT machine also uses stepper motors to control the Z-axis movement (up and down motion) of the placement head, ensuring the component is placed with the correct pressure and alignment.

Rotation: Stepper motors and their drivers can also control the rotation of the placement head or SMT nozzle to correctly orient the SMD components before placement.

5. Feedback and Calibration

Closed-Loop Systems: Advanced stepper motor drivers in SMT machines operate in a closed-loop system, using encoders’ feedback to correct deviations from the desired position, ensuring high precision and reliability in electronic manufacturing services.