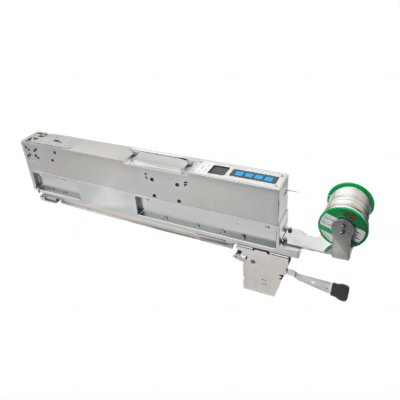

| Kit Number: | FS-SPF-NPM-001 | | Apply for: | For FUJI NXT, Hanwha SM482, Panasonic CM602, NPM | | Material: | Tin solder wire, 0805/0603 | | LxWxH(mm): | 550x88x109 5.8kg | | |

. Automatic solder preform feeders offer several advantages when used with pick and place machines:

. Efficiency: PCB assembly solder preform feeders automate the process of supplying solder preforms to the pick and place machine, eliminating the need for manual handling. This leads to increased efficiency in the production line, as it reduces the time and labor required for soldering operations.

. Consistency: By automating the feeding process, these feeders help maintain consistent solder joint formation across multiple PCBs. Consistency is vital for product quality and reliability, especially in electronics manufacturing.

. Reduced Waste: Manual handling of solder preforms can result in waste due to mishandling or misplacement. Automatic solder preform feeders minimize such waste by precisely delivering the required amount of solder material, reducing scrap, and improving cost-effectiveness.

. Enhanced Safety: Manual soldering operations involve exposure to high temperatures and potentially hazardous materials. Automated soldering preform feeders help mitigate safety risks by reducing the need for manual intervention in the soldering process, thus improving the working environment for operators.

. Flexibility: Many automatic solder preform feeders are designed to accommodate various sizes and shapes of solder preforms. This flexibility allows manufacturers to adapt to different PCB designs and soldering requirements without significant retooling or setup changes.

. Increased Productivity: By streamlining the soldering process and minimizing downtime associated with manual handling, automatic feeders contribute to higher overall productivity in the manufacturing environment.

. Integration Capabilities: Efficient solder preform handling solutions can often be integrated seamlessly with existing pick-and-place machines and other automated assembly equipment. This integration facilitates smoother operation and reduces the complexity of the manufacturing setup.